4. Production

Each cymbal is unique in its sound characteristics. Modern manufacturing techniques guarantee long-lasting quality and more consistent models, yet small differences still result in subtly different sound properties even among identical models of cymbal.

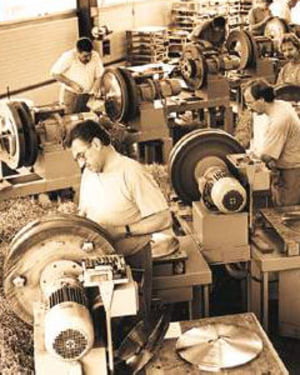

Generally, high-quality professional cymbal manufacturing has changed little during the past century. Though machines have made the process easier and more consistent, they are used primarily to supplement the talents of the cymbal smiths to create unique and high-quality musical instruments. However, mass production and automation have also been used to create lower-priced cymbals with varying results. It seems that more automated manufacturing processes result in less unique cymbal tones and character. Always let your ears be your guide.

The Manufacturing Process

Every cymbal company has your sound somewhere in their warehouse. Companies employ a creative director who maintains constant contact with top professional endorsers to collect design ideas for new cymbals. The material, type of cymbal bell, the profile and taper of the cymbal as well as the lathing or hammering patterns are all designed to yield a certain sound.

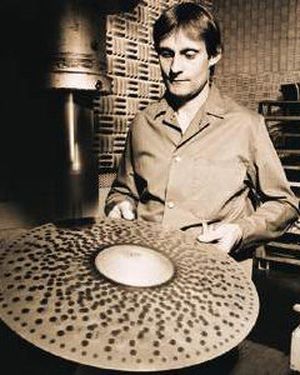

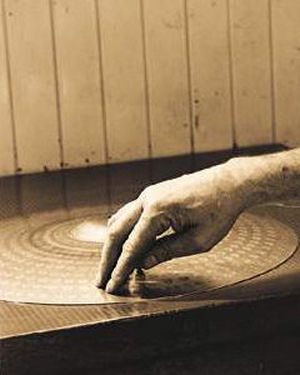

Cymbals are first poured as blanks with the proprietary alloys that each cymbal manufacturer uses. The exact composition of these alloys is a closely guarded secret. The centre of each blank is heated (Fig. 1) and the bell is formed (Fig. 2).

Fig.1

Fig.2

The next step is to make a hole in the centre of the cymbal (Fig. 3). Some cymbals go through another heat treatment in a high temperature furnace, to add special sound characteristics. The molecular structure of a cymbal is affected by heat, causing the metal to become harder and/or more flexible. (Fig. 4)

Fig.3

Fig.4

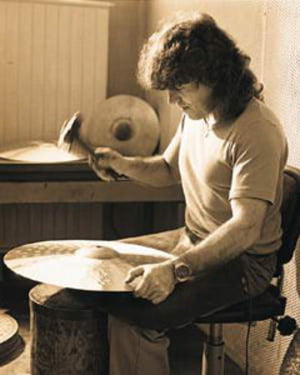

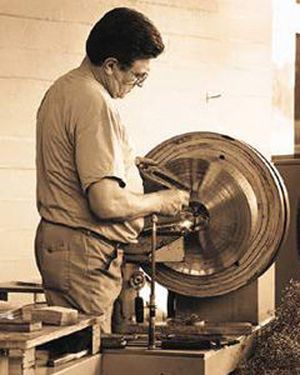

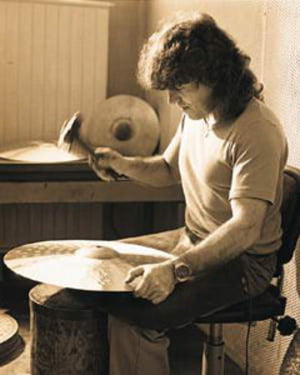

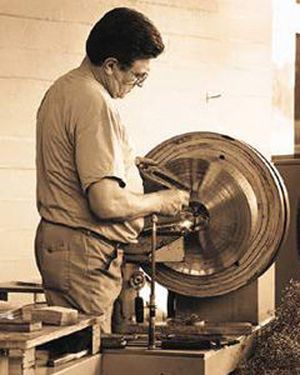

The most important part of cymbal making is hammering the cymbals. Some traditional cymbal making processes use hand hammering for this labour-intensive step, but most cymbal smiths take advantage of pneumatic hammers. Despite the aid of the hammering device, the cymbal maker has control of the speed, pattern, strength and many other important parameters during hammering (Fig. 5) . Form corrections and final hammering are often done with just an anvil and a hammer (Fig. 6).

Fig.5

Fig.6

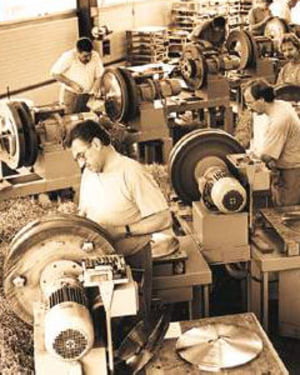

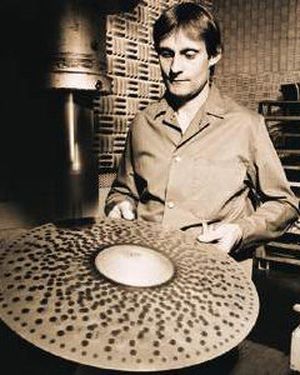

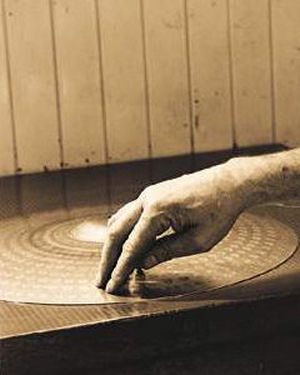

Grooves may be lathed into the surface of the cymbal with a sharp whetstone, ensuring accurate control of thickness. This production method is accurate to within 0.05mm (the thickness of a human hair). (Fig. 7/8)

Fig.7

Fig.8

The shape of the cymbal is constantly checked during the hammering process (Fig. 9/10).

Fig.9

Fig.10

Special care is taken to ensure that cymbals are evenly shaped and lie flat on a custom designed steel table (Fig. 11). The thickness of the cymbal is checked by manually turning and measuring it with a special micrometer (Fig. 12).

Fig.11

Fig.12

After this step the cymbal edges are straightened and the manufacturers logo and model are marked on the cymbal (Fig. 13). Next, the cymbals receive a special protective coating to prevent oxidation (Fig. 14).

Fig.13

Fig.14

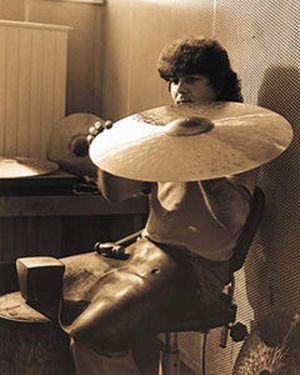

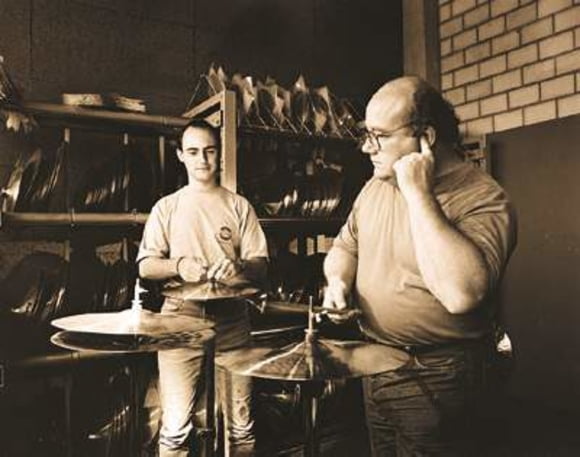

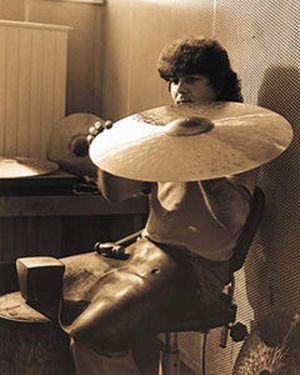

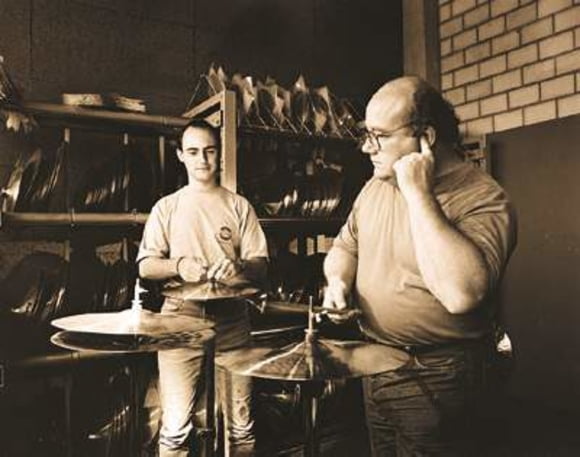

In the final step of the manufacturing process the sound of each cymbal is compared to that of a reference cymbal created as the prototype for the line (Fig.15). If a cymbal varies from the reference cymbal, it is melted and recycled. This ensures that only instruments with ideal sound characteristics and quality are shipped to customers.

Fig.15